Five Impacts of DOE Compliant Transformers

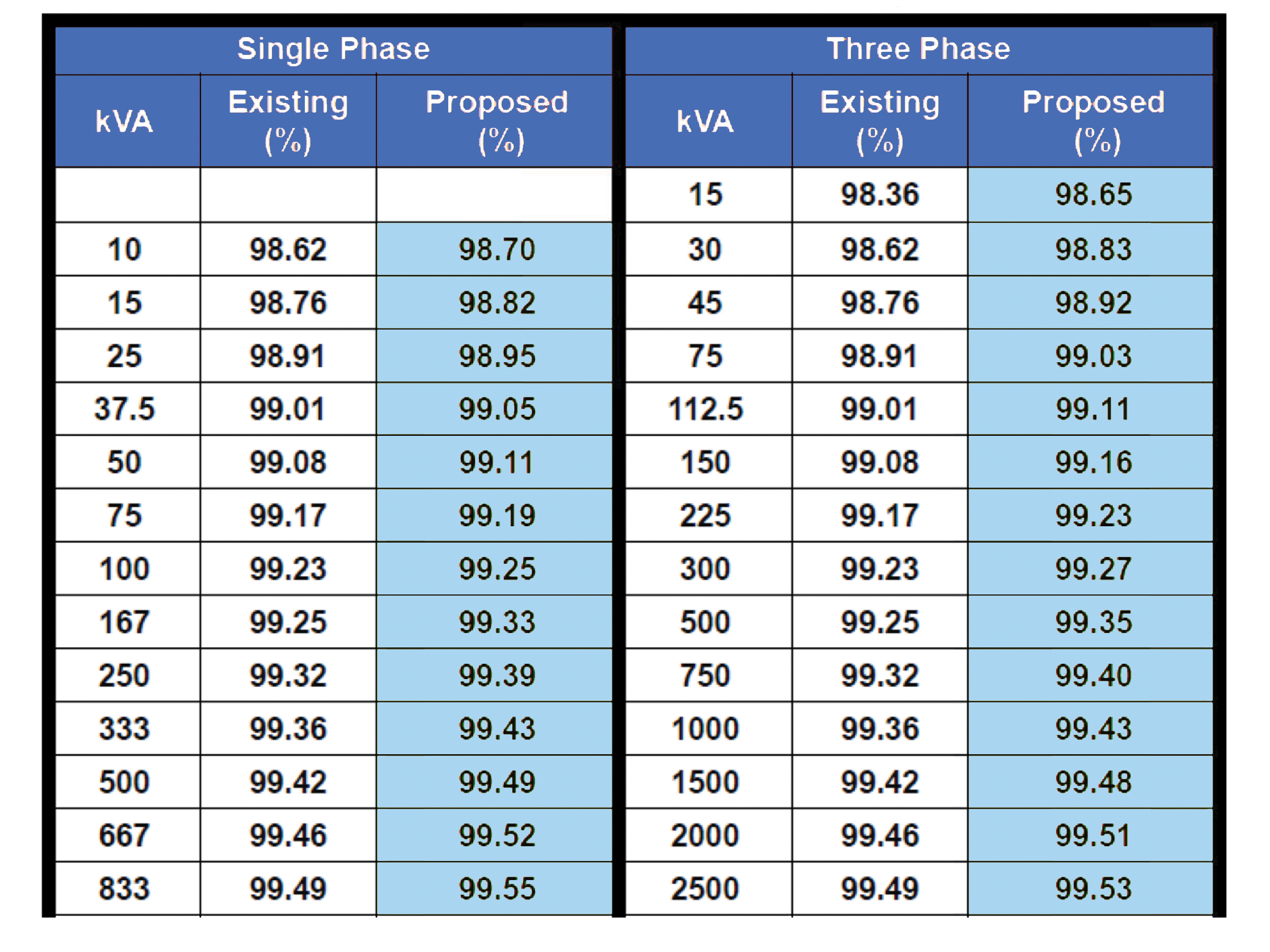

On April 18, 2013, The U.S. Department of Energy published amended efficiency standards for all covered distribution transformers, effective 1/1/2016. Given the upcoming transition deadline, we’ve broken down the DOE’s decision into the FIVE most significant impacts on utility users and commercial/industrial customers.

Here’s what you need to know.

1. The DOE will Enforce New Standards Effective January 1, 2016

Any transformer shipped after December 12, 2015, from any manufacturer, must conform to the new DOE efficiency standard. In order to accommodate the transition, all new transformer orders or existing blanket-based transformer orders must be re-designed and re-quoted. Transformers in customer inventory do not need to be modified or discarded. They can be used for normal business needs.

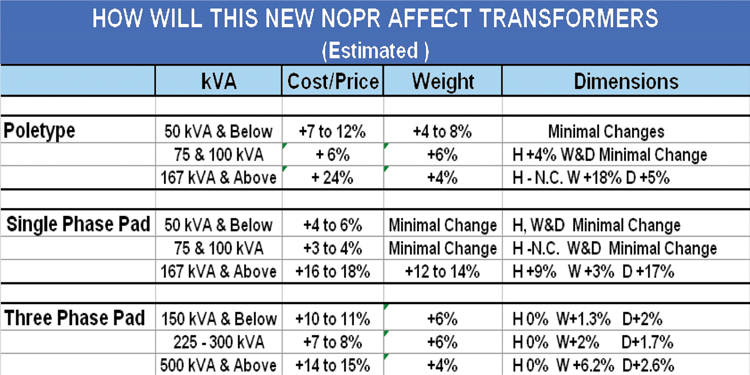

2. Dimensions and Weight of Current Transformers will change

2. Dimensions and Weight of Current Transformers will change

New standards will have an effect on overall weight and size of in many instances. Transformers dimensions will increase for overhead and three-phase padmount transformers, especially in the larger kVA sizes. Transformer weight will increase by 4-8% for overhead transformers, and 5-6% for three-phase padmount transformers (depending on specs and design).

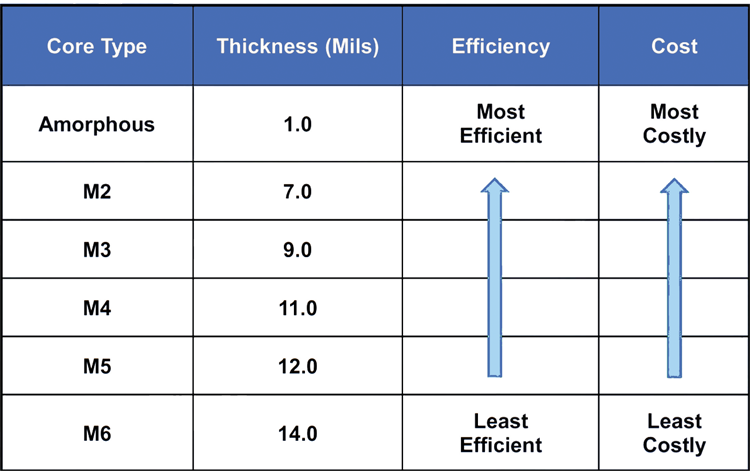

3. Core Materials will be more expensive

Efficient transformers will require higher grades of core steel. This will create higher demand for M2, M3 and amorphous metals. Raw material suppliers may have difficulty producing enough material for the new demand, putting pressure on steel costs. The more efficient material, the more costly it is to produce. Thinner (more efficient) steel requires same “run time” as heavier material.

4. Installation practices may be impacted

While the more efficient materials will most often result in minor size changes, in some cases poles may need to be increased in class and size in order to accommodate the increased weight and electrical clearances. Likewise, fiberglass and concrete pads may need to be redesigned in order to accommodate the dimensions of the newer, DOE-compliant three-phase padmount transformers.

In some cases, material handling (fork trucks, line trucks, derricks) will need to be addressed to account for changes in weight and size of the new transformers.

5. Plan to meet DOE Deadlines

Howard industries and manufacturers alike need adequate time to transition production to DOE compliant manufacturing. Howard will begin quoting DOE-compliant designs on July 31, 2015. Consequently, Howard will cease production of all non-complaint transformers by September 1, 2015. Ideally, all engineering specs will be completed by July 31, 2015, and customers should plan to submit quotation evaluations well before this date. To receive a quote from Howard Industries, contact us at moc.s1772245006elas-1772245006rewop1772245006@sela1772245006s1772245006