Self-Supporting Structures

Self-Supporting Structures

Guy wires. Those thin galvanized steel cables sprouting off utility poles and electrical towers. They provide support and stability for angle and dead-end structures and are generally simple, effective and easy to implement; however, there are shortfalls.

Uneven terrain, customer siting demands and dense urban planning force utilities to abandon traditional round poles and guy wires. Fortunately, there are now innovative options for utilities facing these pressures including our choice: Self-Supporting Structures from Laminated Wood Systems Inc.

Self-Supporting Structures are unguyed poles able to resist tremendous horizontal loads. Contrived of laminated slats, glued together, the final pole is cut into an angular beam, reinforced and buried securely in compound aggregate.

Why consider Self-Supporting Structures?

- Shorter lead times than steel/fiberglass

- Rot and woodpecker resistant

- Aesthetically pleasing wood from renewable sources

- Laminated timber insulates better than steel/concrete

- 60+ year service life

- Easy modification in field; can be drilled and climbed with hooks

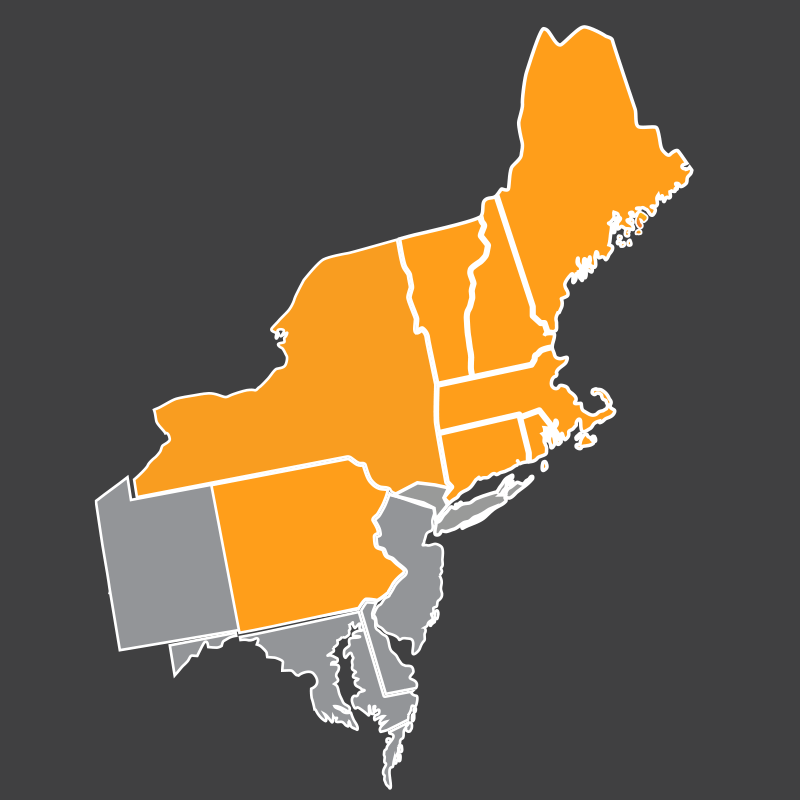

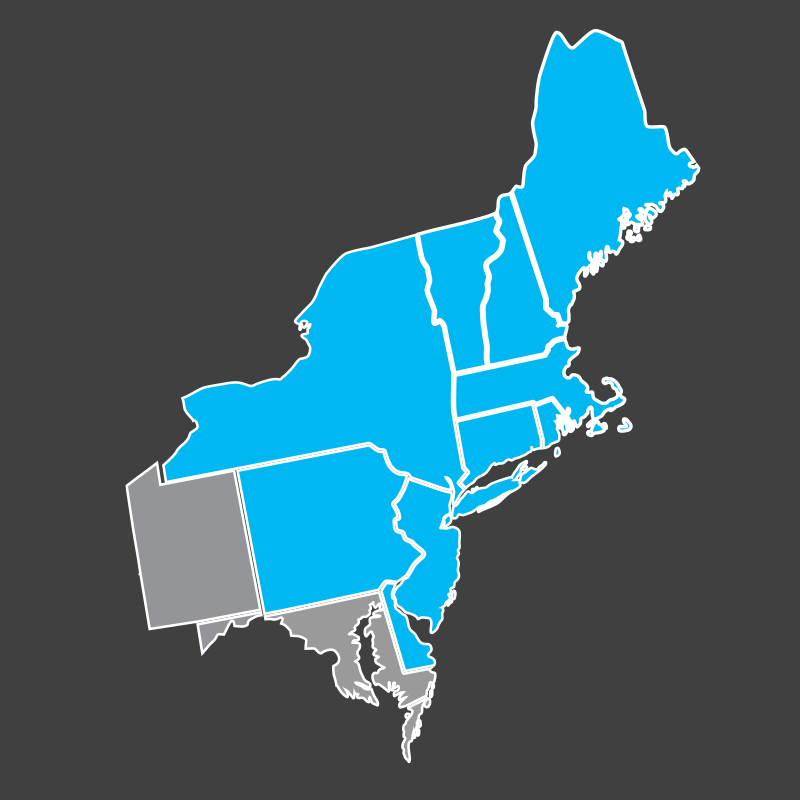

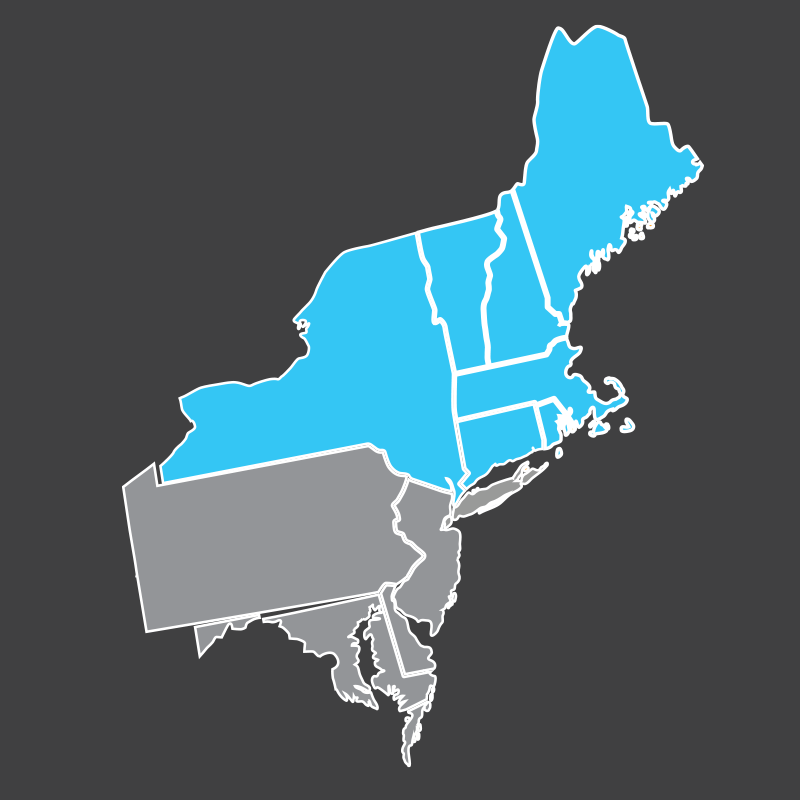

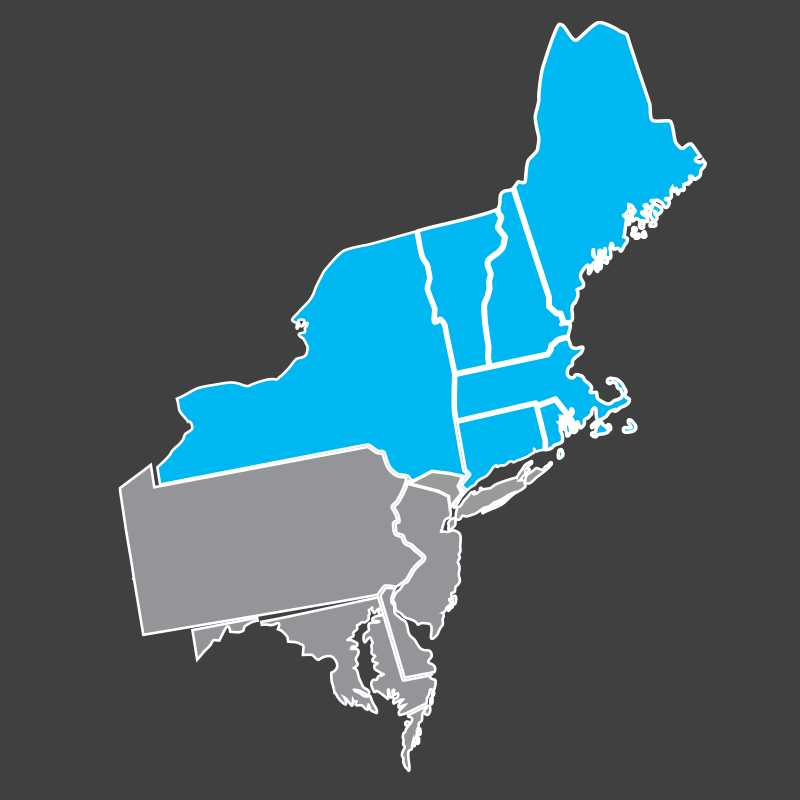

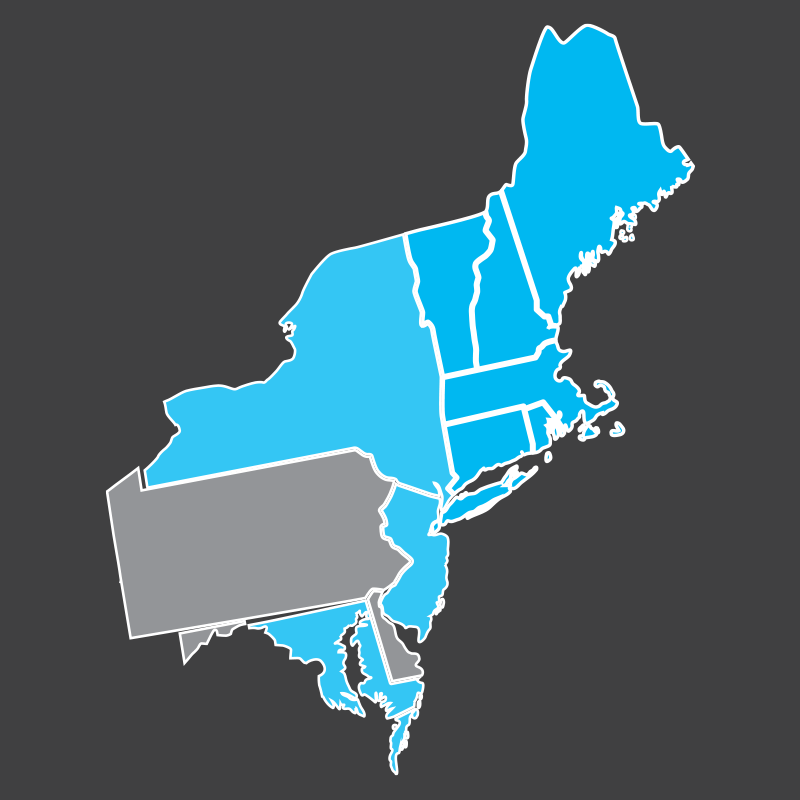

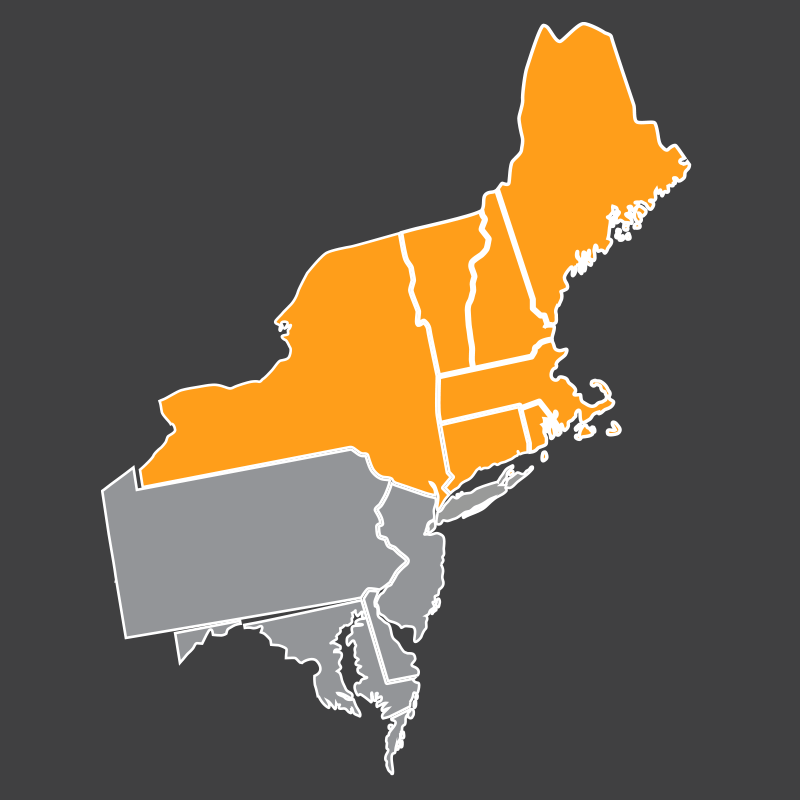

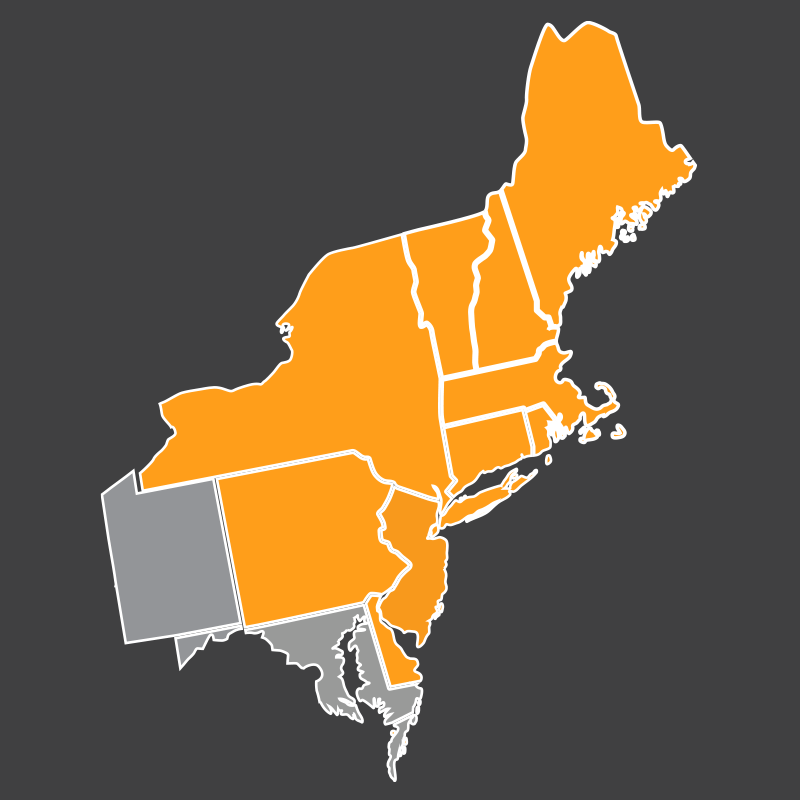

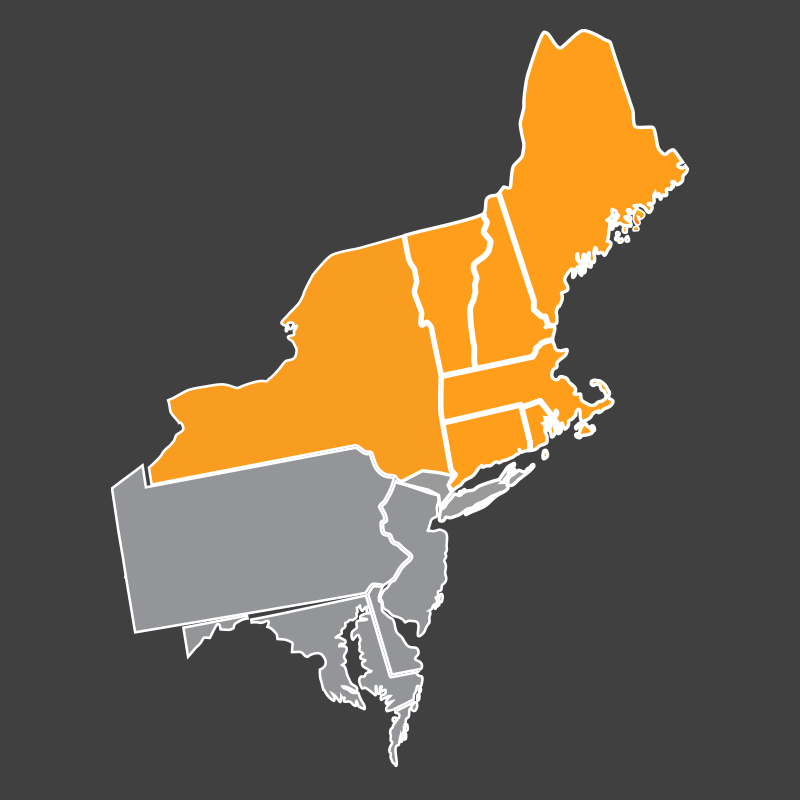

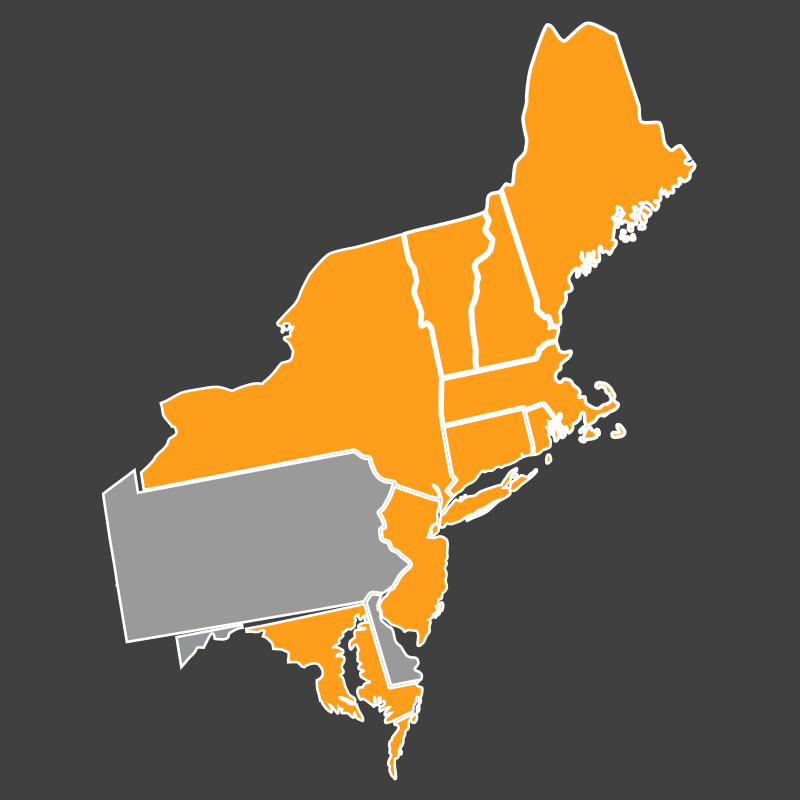

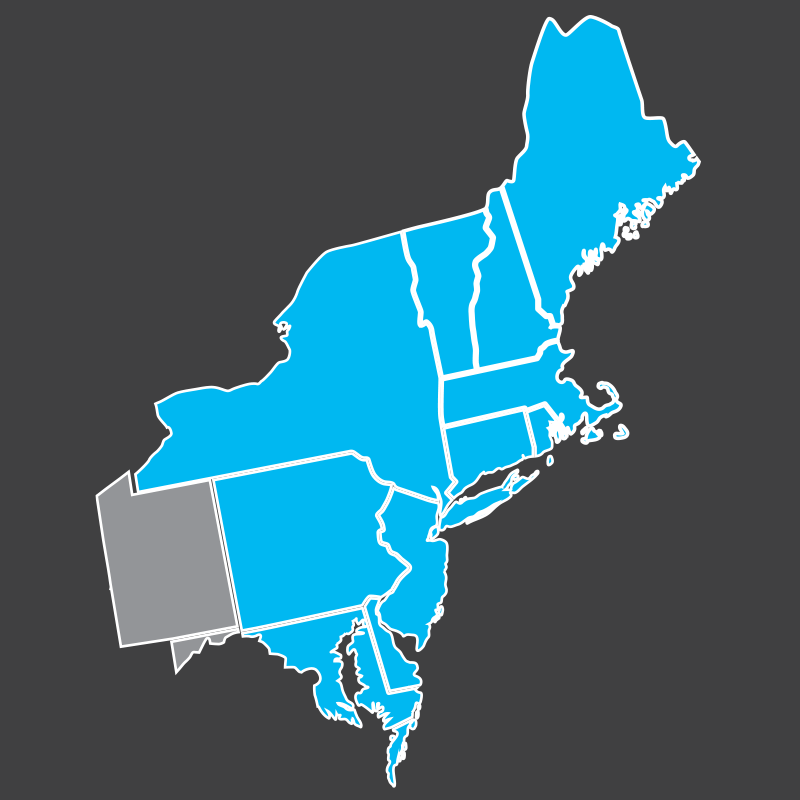

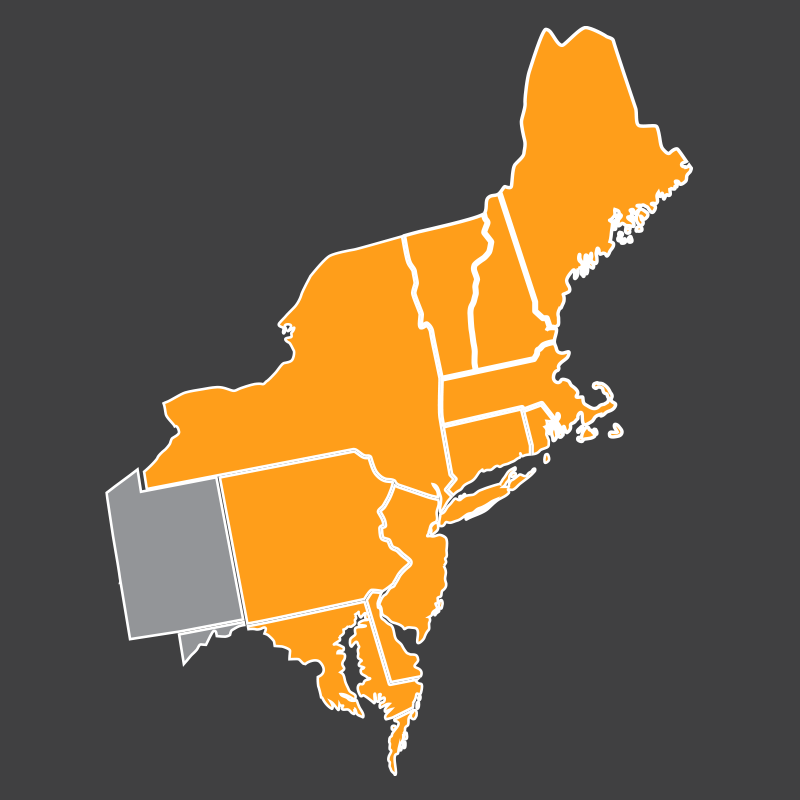

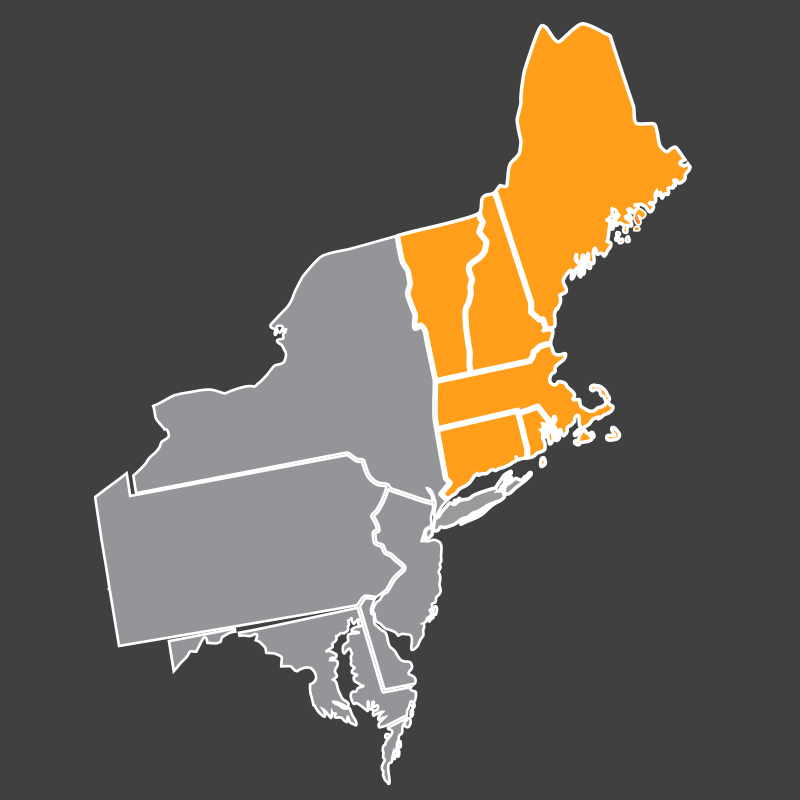

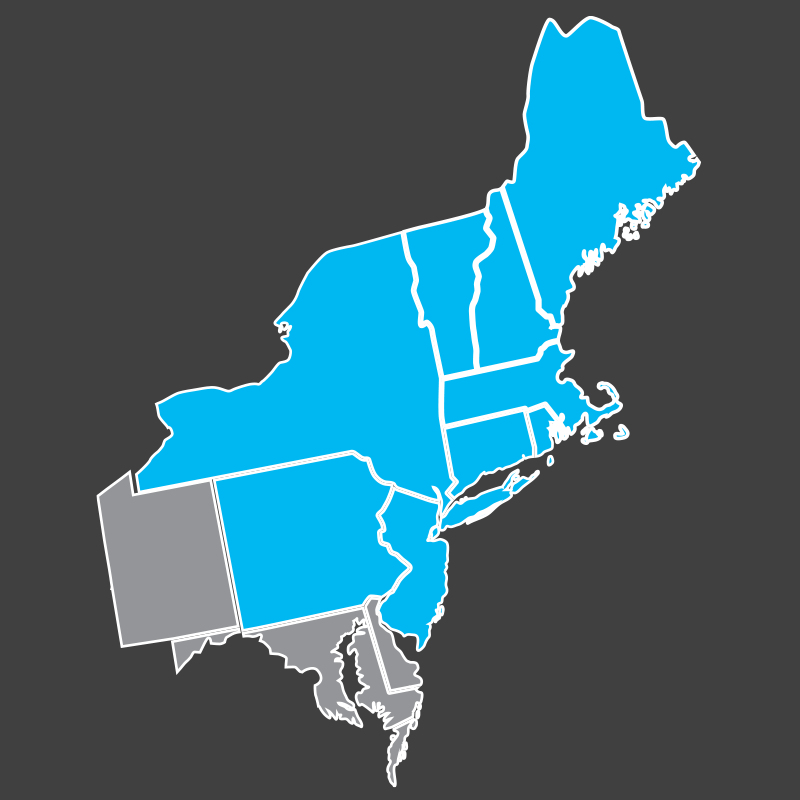

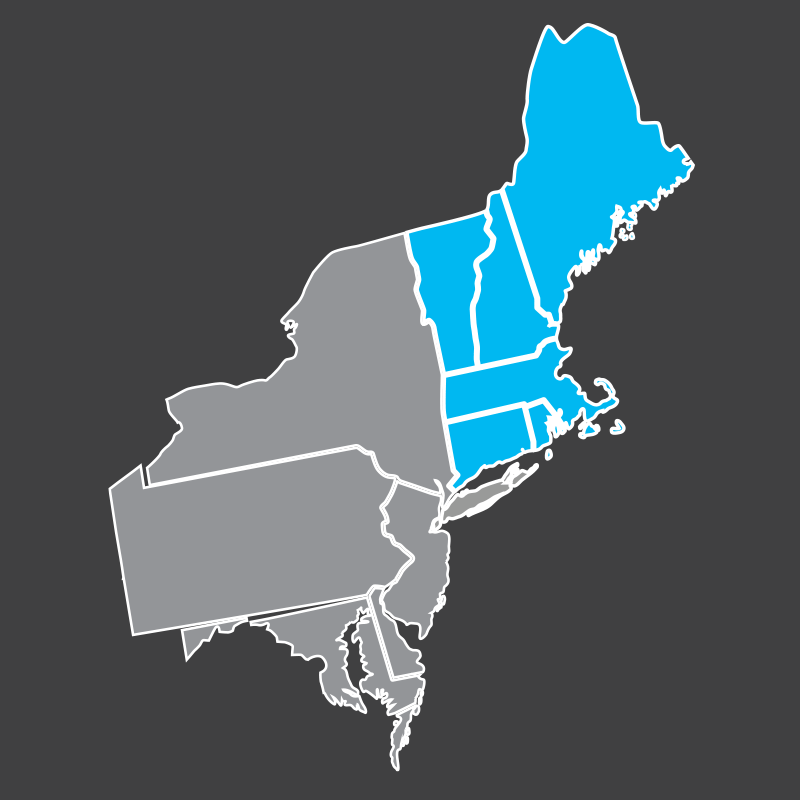

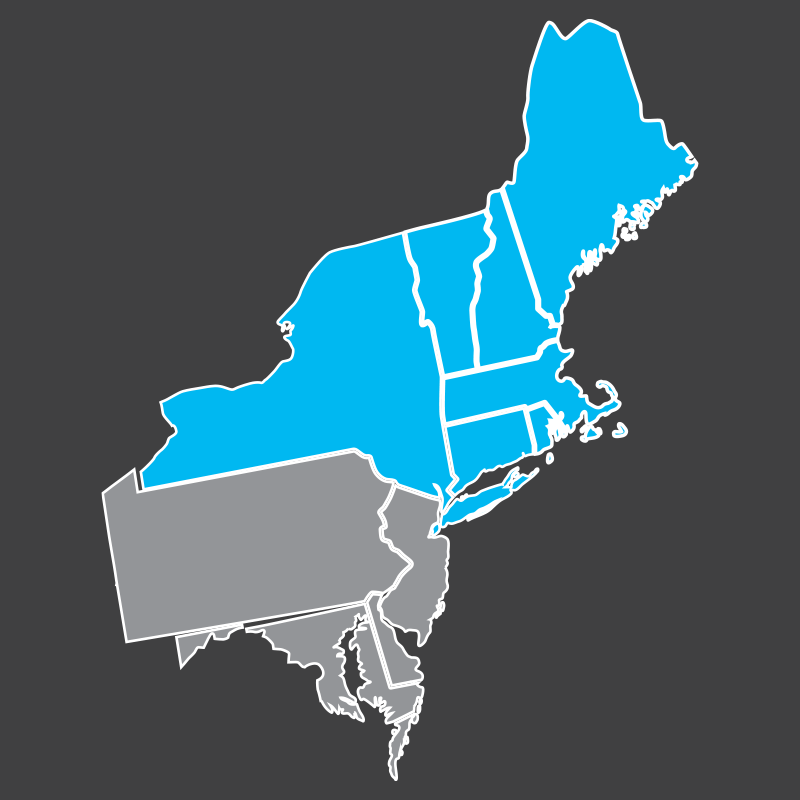

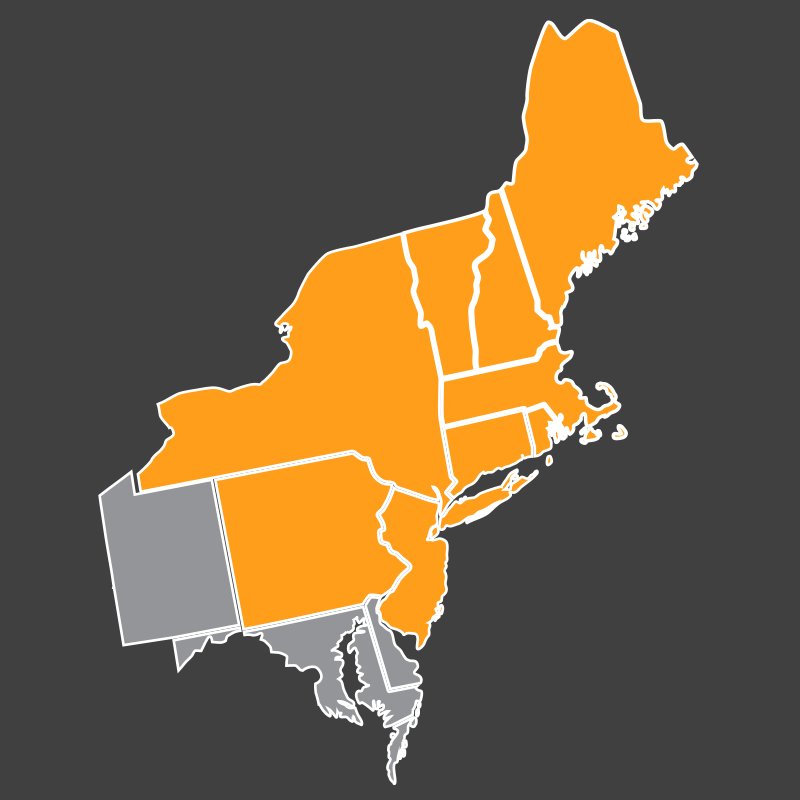

- Proven track record with functioning poles in 50 states

- Meet all industry standards

With 20-years of experience, Laminated Wood Systems has reliable manufacturing and a thorough testing component. It begins with kiln-dried lumber, either Coastal Douglas Fir or Southern Yellow Pine. Each board is stress and bend tested prior to gluing. This allows for “grading” of the material.

Additionally, each batch of glue is subject to a bonding-strength test before application. Poles are then clamped for eight hours, creating a billet, and the glue is cured by high frequency energy. They are then cut diagonally and preserved with Penta and Oil.

When everything is said and done, you’re left with a sleek and easily modifiable design.

We love the free perks.

- LWS has opted to size poles for its customers free of charge. They offer an Online Engineering Worksheet for Raked Poles that will get you recommendations and a quick quote for your project.

- Laminated Wood Systems will develop a custom foundation for your particular set up (also free) and help you decide on the best procedure and approach.

- Wondering how your new pole will look? LWS’ Engineering Team will provide a photo simulation – you guessed it, free. Just take some pictures of your existing structures and send them (along with the completed worksheet) to moc.s1772245080elas-1772245080rewop1772245080@sela1772245080s1772245080 for a professional simulation you can take to your customer or local siting council.

Final Verdict: Laminated Wood Systems provides a dynamic resource for custom structures where guyed support is not an option. Check out this PDF with full specifications of raked poles and be sure to drop us a line in the comments below if you have any questions.